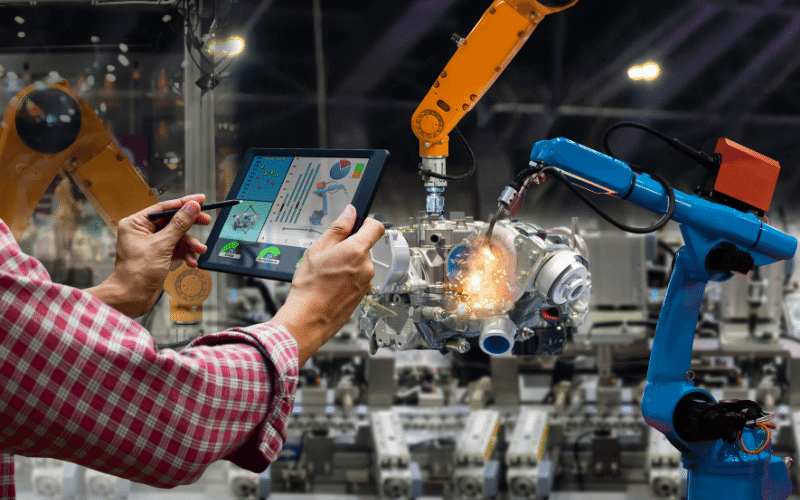

Industrial robots are mechanical systems used in manufacturing. They are capable of moving in three or more axes, are programmable and autonomous. They are small autonomous mechanical systems suited for small and light tasks and are perfectly suited for workstations or workbench scenarios.

In the past, robots in the manufacturing industry were big, bulky, and required a lot of space. They were fixed and could only be programmed to perform only one type of task. Today industrial robots have been miniaturized and can be moved from one point to another. This gives them the ability to perform more than one set function or task. This makes small industrial robots very versatile and practical.

There are numerous benefits of small industrial robots:

- They are Cost-effective

- They save Time

- They produce High-quality products

- They are versatile

- They offer continuous running time

Cost-effectiveness

Small industrial robots are essentially inexpensive to buy and maintain in comparison to large ones or human labor. This makes them indispensable to any business aiming to make a good profit.

Turning a profit can only be achieved if the production process is as cost-effective as possible. One small industrial robot is capable of performing multiple tasks. Therefore, by investing in multiple robots for performing multiple tasks, a manufacturing plant can make the production process as cost-effective as possible.

Time-saving

Human beings and time work in tandem, in that humans, are bound to the confines of time. They work for a certain period and rest for a given period. This limits production speed, product quantity, and consistency. A robot on the other hand can work none stop. This is because they do not suffer from fatigued as humans do. This ability to work none stop improves the overall quantity of production, maintains consistency and this significantly impacts a company’s bottom line.

High-quality product production

A good quality product translates to improved sales. The opposite is also true. A small industrial robot is capable of continuous and consistent production without fatigue. This continuous consistency results in a high-quality finish and product.

Versatility

Imagine being able to package your products, pick and drop products to and from desired locations, drive in screws and paint-on products, among other functions using one small industrial robot such as a small robotic arm. All these functions are possible by simply loading the arm with the program uniquely coded for each specific function. This kind of versatility is only possible with a collaborative robotic arm.

With the ability of one robotic arm to perform multiple functions, having several of these robots in your assembly line is the best way to boost production and the bottom line. It is also possible to deploy one robotic arm for several functions if you are worried about the cost of deploying several robotic arms at a go.

Continuous running time

Despite its size, a small industrial robot is still a machine. It can run for 24 hours without stopping and will continuously produce products of the desired finish depending on the program loaded into the robot. Unlike humans, the robotic arm suffers no fatigue. Small industrial collaborative robots can perform repetitive tasks without requiring breaks or downtime.

This continuous running and product creation to the same set standard results in uniform finished products in large quantities that are highly desirable and marketable.

Because of the ability of collaborative robots to run continuously day and night, it allows humans enough time to rest and focus on other areas of manufacturing that cannot be done by robots. This is the best way to streamline processes in any manufacturing plant.

Conclusion

The application of small industrial robots to a production line in any manufacturing company is crucial in maintaining high-quality standards for products. It is the best way to boost the company’s bottom line while reducing downtime and increasing production cycles.